How Soft Is a Rigid Nylon Tube?

Polyurethane and nylon are two of the most common materials used for plastic tubing. They are both versatile and work well in applications that require tight bending. However, nylon is more versatile because it can withstand a higher working pressure and is more able to resist abrasion and heat than polyurethane. This is an important difference to consider when choosing the best material for a particular application.

The most common types of nylon tubing are nylon 6 and nylon 66. The difference between these two materials is the number of carbon atoms found in each monomer. Nylon 6 has six carbon atoms, while nylon 66 has two carbon atoms. This makes nylon 6 more resistant to impact and stress than nylon 66.

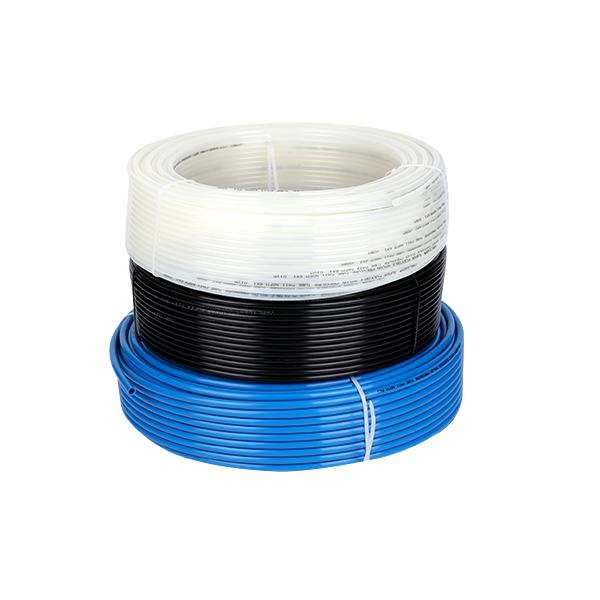

Nylon tubing is manufactured through a plastic extrusion process. The raw material is typically in the form of nurdles, or small beads. These are then gravity-fed into an extruder barrel. The resin also has additives such as colorants and UV inhibitors that are added in liquid form.

If you're unsure of the material you want, it's best to find a reputable manufacturer. These manufacturers will have experience in determining which plastic is best suited for a specific application. They will also have a variety of options available to help you make the right decision.

In addition to ensuring consistency, nylon tubing is tested before it is reel-filled. During the reel filling process, operators check the tubing to ensure quality. Using flexible nylon tubing in weld spatters is not recommended because of the risk of air leakage. You may also encounter air leakage in places with high rotation or vibration.

Semi-rigid nylon tubing is usually used for pneumatic applications and is a popular choice for automotive brake lines. They are also lightweight and dimensionally stable. In addition, they have a wide range of temperature. They are a good choice for applications where high-pressure, high-temperature, and crack-resistant tubing are important.

Another type of plastic tubing is nylon 11. It is a substitute for polyurethane and is suitable for many environments where polyurethane is not appropriate. These environments include fuel, coolant, and air lines. This material is also used in pneumatic tools. Nylon coils are spirals made of nylon tubing. These are used to move compressed air and liquid over shorter distances.

English

English 简体中文

简体中文