Miniature Solenoid Valve

A Miniature Solenoid Valve is an electrically operated valve. This device is used for controlling the flow of gas or liquid through a small orifice. The device has three parts: the core, the seat, and the chamber. The chamber houses the valve's core, which moves towards the yoke 207 when the electromagnet is powered at a predetermined voltage.

The body of a Miniature Solenoid Valve is made up of multiple seat-carrier pieces. Each piece can have a different fluid flow section and a different length. The length of the seat depends on the desired flow rate. The chamber must have a duct diameter that is about one-fourth of the valve's total stroke.

The plunger core extends to a second hollow portion of the body, and is surrounded by a plate 14. The central part of plate 14 is made of elastomer. This plate forms the first valve member of the valve. The cavity is leveled to ensure the valve member 15 is flush with the chamber's radially extending surface.

The body of a Miniature Solenoid Valve has an orifice between chamber 13 and top surface 3. The orifice 61 is primarily used for manual control. A cylindrical insert 62 is inserted into the orifice and has an external spike means for securing. It also has a diametral slot 65 and a top shoulder 64. The top shoulder of the insert is held in place by a resilient pin 66.

The miniaturized Miniature Solenoid Valve has a plunger core and an electromagnet. The plunger core is held in place by the moving equipment. The axial duct segment carries the second member of the valve. The seat is located in a common plane transverse to the valve.

A Miniature Solenoid Valve is an ideal choice for applications requiring precision flow control. In space applications, efficiency in size, weight, and power usage are essential. The Marotta mini Solenoid Valve meets these requirements, while delivering a compact design and reliable construction. It can operate in low-power situations, which is critical for space applications.

Miniature Solenoid Valves are available in a variety of designs and materials. Some are available with two or three orifices. Some are able to be customized to meet specific application requirements. They are often used in medical devices, laboratory instruments, and other environments.

In addition to the Single-Way Miniature Solenoid Valve, the Three-Way Solenoid Valve is also a great option. These valves are used when pressure is needed to mix gases and liquids. The HK5 is another popular choice for these applications. A Miniature Solenoid Valve also makes a good choice for a pneumatic pilot valve.

A Miniature Solenoid Valve is an energy-efficient, low-cost solution for applications where precision is critical. Their small size and compact design makes them easy to use. They also have a very fast response time. They also require little maintenance.

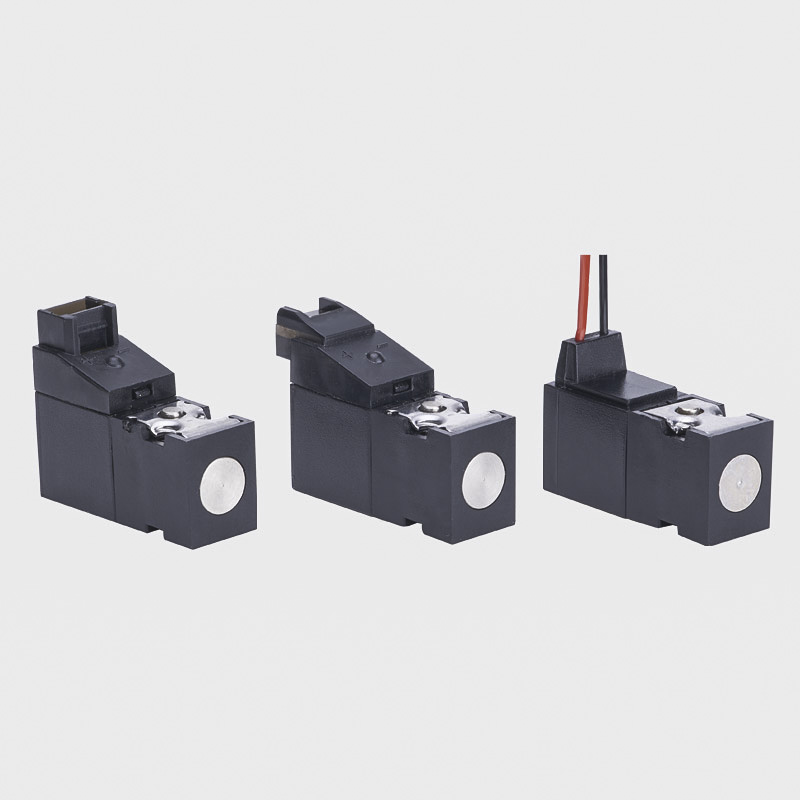

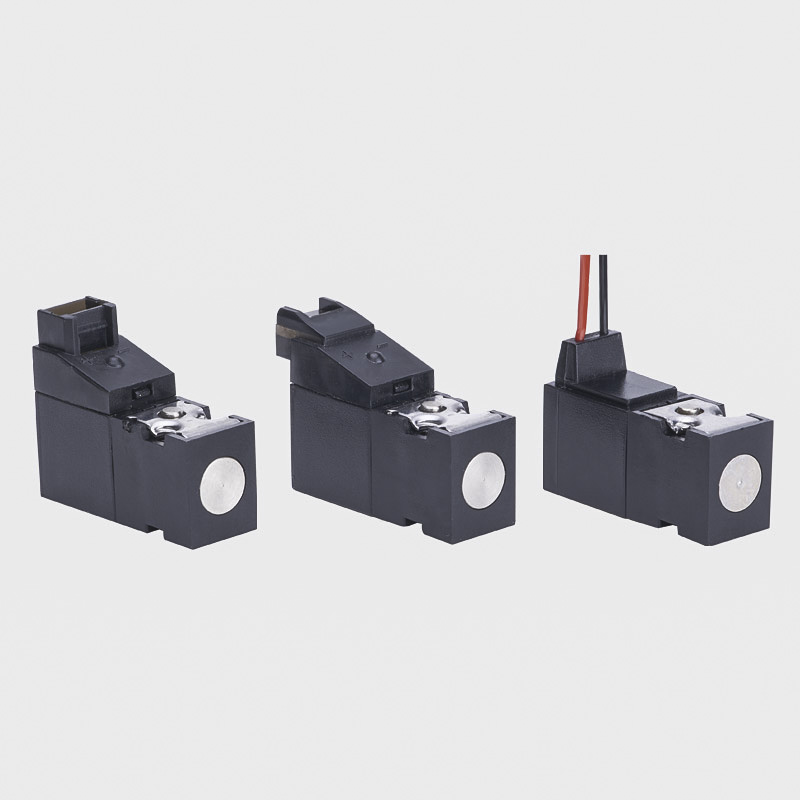

371 Series Direct Acting Miniature Electromagnetic Valve (10mm) Customizable Vacuum Breaker Solenoid Valve

The 371 series direct-acting miniature solenoid valve can be installed in a plate connection or used directly with a single valve seat. It can control the operation of a single-acting cylinder at high frequency, and can also be used as a pilot valve for a large flow valve. There are two functions: normally closed (NC) and normally open (NO), and two shapes: two-hole self-draining and three-hole valve plate exhaust. Special instructions are required when using in vacuum. Two-position two-way, two-position three-way, normally closed (NC) or normally open (NO) Can be used in vacuum (100kpa)

371 Series Direct Acting Miniature Electromagnetic Valve (10mm) Customizable Vacuum Breaker Solenoid Valve

The 371 series direct-acting miniature solenoid valve can be installed in a plate connection or used directly with a single valve seat. It can control the operation of a single-acting cylinder at high frequency, and can also be used as a pilot valve for a large flow valve. There are two functions: normally closed (NC) and normally open (NO), and two shapes: two-hole self-draining and three-hole valve plate exhaust. Special instructions are required when using in vacuum. Two-position two-way, two-position three-way, normally closed (NC) or normally open (NO) Can be used in vacuum (100kpa)

English

English 简体中文

简体中文