What are the significant features of the 372 Series Direct Acting Miniature Electromagnetic Valve in terms of power and heat generation?

The core advantage of the 372 Series Direct Acting Miniature Electromagnetic Valve lies in its direct drive design principle. Compared with traditional pilot-operated solenoid valves, the direct-acting design significantly reduces the intermediate transmission mechanism, thereby directly driving the switching action of the valve core through electromagnetic force. Not only does this design simplify the structure, it also significantly reduces the need for electromagnetic forces since there is no additional mechanical resistance to overcome. Therefore, under the same working conditions, the 372 series solenoid valve requires less electrical energy, achieving efficient energy conversion.

During long-term use, the low-power characteristics of the 372 Series Direct Acting Miniature Electromagnetic Valve have shown great energy-saving potential. This energy-saving effect is particularly obvious for automated production lines that are deployed on a large scale or operate at high frequencies. The reduced energy consumption not only reduces the company's operating costs, but also actively responds to the global call for energy conservation and emission reduction, winning a good social image for the company.

In addition to the direct reduction in energy consumption, low power also brings significant reductions in equipment operating costs. First, low power means a smaller power load, which is particularly important in areas with tight power supply or high electricity prices. Secondly, due to the small amount of heat generated, the heat dissipation system of the solenoid valve can be simpler, reducing the investment and operating costs of heat dissipation equipment. In addition, low power reduces equipment failures and the need for repairs due to overheating, further reducing maintenance costs.

Low heat generation is a highlight of the 372 Series Direct Acting Miniature Electromagnetic Valve. During long-term operation, the reduction in heat generation effectively suppresses the temperature rise inside the equipment and avoids the negative impact of high temperature on material performance. This not only extends the service life of the solenoid valve, but also maintains the stability of its performance. In addition, the low calorific value also reduces thermal stress caused by temperature fluctuations, reducing the risk of wear and fatigue damage of mechanical components.

Low heat generation also brings a good user experience. In high-temperature or closed working environments, low-heat solenoid valves can reduce the dissipation of heat to the surrounding environment, lower the ambient temperature, and improve the working conditions of workers. At the same time, low calorific value also reduces noise and vibration caused by heat accumulation, improving the overall operating quality of the equipment and the comfort of the working environment.

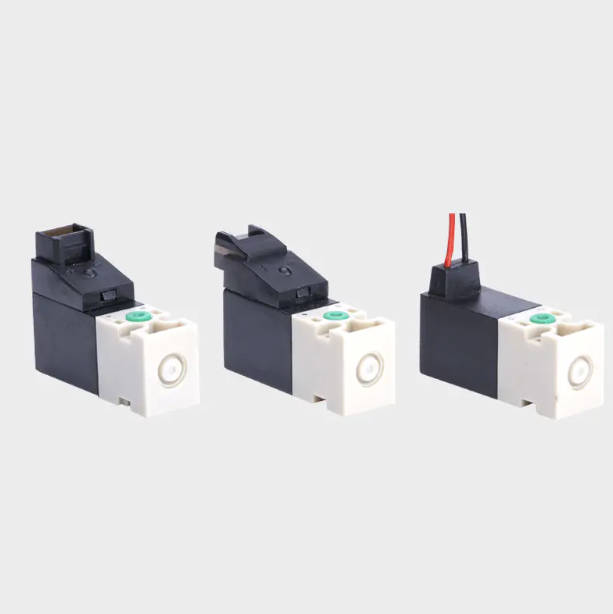

The notable features of the 372 Series Direct Acting Miniature Electromagnetic Valve in terms of power and heat generation include low power, low heat generation, and strong ability to energize for a long time. These characteristics make this series of solenoid valves have broad application prospects in industrial automation, mechanical equipment and other fields.

English

English 简体中文

简体中文